A reputable membrane switch manufacturer offers both sample and bulk options.

A reputable membrane switch manufacturer offers both sample and bulk options.

Blog Article

What to Search for When Selecting a Membrane Layer Switch for Your Project

When you're selecting a membrane button for your task, several essential elements enter into play. You'll require to assume concerning the products, layout, and how well it aligns with your brand name. Sturdiness and usability are essential, however so is the track record of the supplier. Comprehending these aspects can help you make an informed choice-- one that balances top quality and expense properly. Let's explore what you must consider to ensure your option fulfills all your task needs.

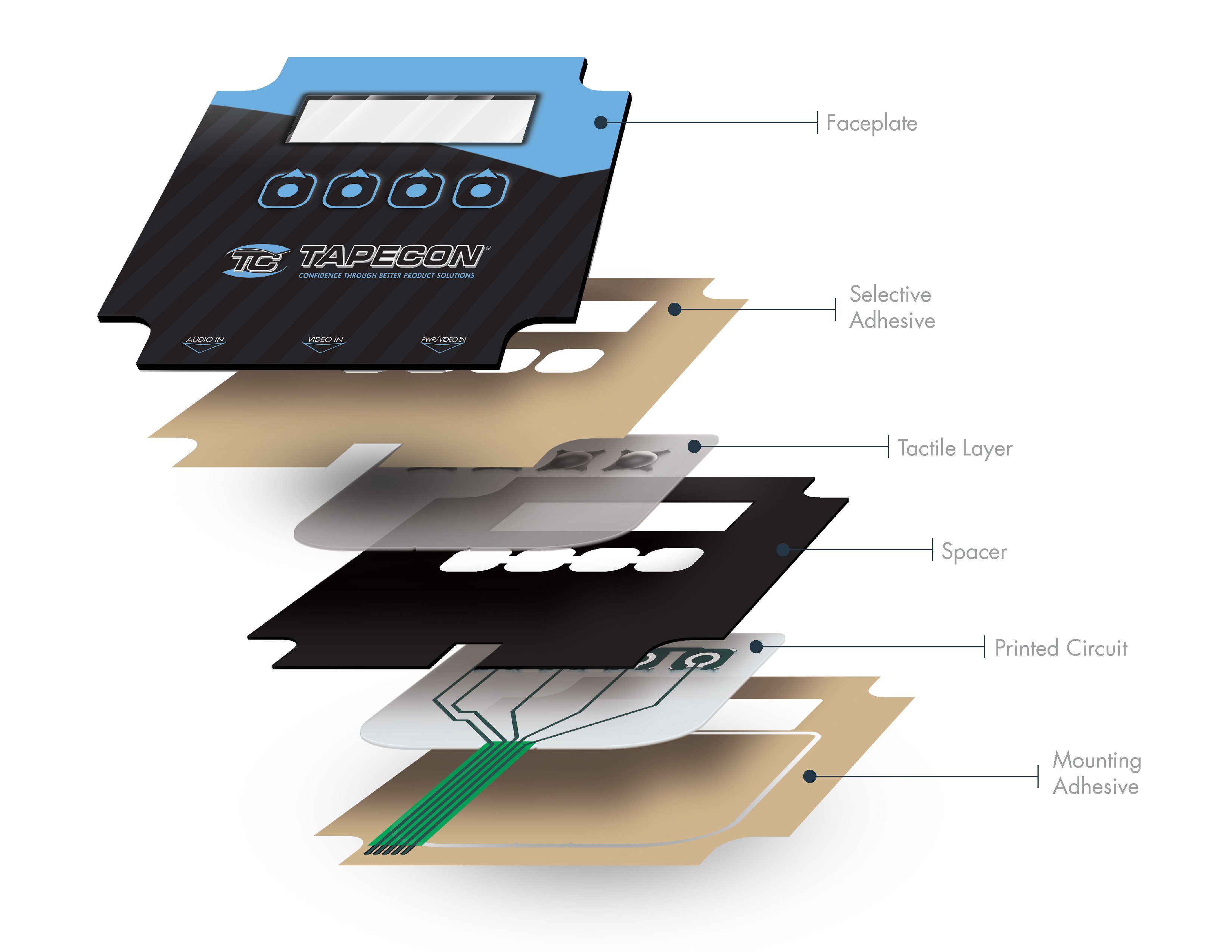

Comprehending Membrane Switch Over Parts

When you plunge right into the world of membrane layer buttons, it's crucial to understand the crucial components that make them work. Beneath that, the spacer layer guarantees there's sufficient distance between the circuit and the overlay, allowing the button to turn on without consistent stress.

The circuit layer, frequently made from published conductive inks, develops the electrical pathways. When you push a button, the circuit shuts, sending out a signal to the tool. Comprehending how these layers collaborate aids you pick a membrane layer switch that's trusted and fits your task requirements. Pay very close attention to the thickness and material of each layer, as these aspects affect resilience and functionality in various settings.

Product Selection and Its Influence

Choosing the best products for your membrane layer switch can significantly influence its efficiency and long life. The choice of substratum, usually polyester or polycarbonate, influences toughness and flexibility. Polyester is more abrasion-resistant, while polycarbonate offers much better clearness and stamina.

Next, consider the adhesive. It requires to withstand ecological factors like wetness and temperature modifications. A solid glue warranties that your membrane button remains intact over time.

Do not forget the visuals overlay. The printing method used, whether silkscreen or electronic, influences the switch's visual appeals and long life. Premium inks will resist fading and scraping, maintaining a professional look.

Lastly, think of environmental problems. If your tool will be revealed to extreme chemicals or extreme temperatures, choose products designed to withstand these difficulties. Your selections in materials will ultimately identify the button's reliability and customer fulfillment.

Design Factors To Consider for Individual Experience

Choosing the ideal products lays the structure for an effective membrane button, yet the design also plays a significant function in customer experience. You'll desire to reflect on just how the design influences functionality (membrane switch manufacturer). Maintain switches and symbols instinctive and well-spaced, making it very easy for users to browse without complication

Color and comparison are likewise essential; guarantee that your layout is visually attractive yet still useful. High comparison assists individuals easily recognize switches, especially in low-light conditions.

Finally, reflect on the total visual. A streamlined and contemporary design can elevate customer assumption and make your product a lot more enticing. Stabilizing capability with an engaging layout will result in a better individual experience and ultimately, a more successful product.

Ecological Aspects and Sturdiness

When picking a membrane button, you need to take into account exactly how it'll execute in various environments. Variables like temperature resistance, moisture and chemical direct exposure, and mechanical wear can considerably influence its resilience. Comprehending these aspects will assist you choose a switch that withstands your details problems.

Temperature Level Resistance Needs

As environmental problems can vary extensively, comprehending temperature resistance is necessary for ensuring the resilience of your membrane switch. Make sure to inspect the specs of the materials made use of in the switch, like the sticky and overlay, as they straight impact performance. By selecting a membrane layer button with appropriate temperature level resistance, you'll improve its lifespan and keep performance in tough atmospheres.

Wetness and Chemical Direct Exposure

Moisture and chemical direct exposure can greatly influence the performance and long life of your membrane layer switch, so it's crucial to comprehend the setting in which it will be used. If your project involves high moisture or direct exposure to fluids, search for safety layers and sealants that can enhance resistance to wetness. In addition, think about the kinds of chemicals your button may come across. Certain materials can deteriorate when revealed to solvents, oils, or extreme cleansers. Selecting the best products, like polycarbonate or polyester, can aid stand up to these components. Always speak with the supplier's requirements for chemical compatibility to assure your membrane layer switch maintains its functionality over time. By prioritizing wetness and chemical resistance, you can boost the resilience of your button in challenging environments.

Mechanical Use and Tear

While you may focus on features like aesthetics and performance in your membrane layer button, mechanical wear and tear can considerably influence its efficiency over time. why not find out more Regular pushing can lead to degradation of products, causing concerns like responsive feedback loss or even switch failure. Picking a resilient button warranties longevity and integrity, preventing costly replacements and downtime in your task.

Modification Options for Branding

When it concerns branding your membrane layer switch, modification alternatives are essential. You can pick layout elements and shades that mirror your brand name, together with particular logo placement and size to enhance presence. In addition, choosing the appropriate products and appearances can boost the total look, making your item stand apart.

Style Aspects and Colors

A variety of layout components and colors can make your membrane button not just functional however likewise visually attractive, boosting your brand identification. When picking colors, consider your brand's palette; they need to reverberate with your audience and stimulate the ideal emotions. You can additionally check out various coatings like matte or shiny to develop various aesthetic impacts. Don't ignore structures; including a responsive component can enhance user experience and make your switch attract attention. Think about including personalized graphics or patterns that straighten with your brand name message. By attentively selecting style components and colors, you not only create an item that looks fantastic yet additionally strengthens your branding regularly and successfully.

Logo Positioning and Dimension

After settling your layout elements and shades, the next step is to focus on logo design positioning and size. Your logo design is a vital facet of your branding, so you'll want it to stand apart without frustrating various other style elements. Assess where your logo will certainly be most visible and impactful; usual positionings consist of the top or center of the switch.

Don't forget to contemplate how the logo aligns with user communication. This interest to detail will certainly improve both functionality and brand identity in your job.

Material and Structure Choices

Selecting the ideal products and appearances for your membrane layer switch can considerably improve both its functionality and aesthetic allure. You'll desire to examine options like polyester or polycarbonate, as they offer resilience and resistance to wear. The appearance of the surface additionally plays a vital role; smooth finishes give a sleek look, while distinctive surface areas can enhance grip and responsive feedback.

Personalizing the products and structures allows you to mirror your brand identity properly. For instance, you could choose a matte coating to convey refinement or a glossy search for a modern-day touch - membrane switch these details manufacturer. Don't forget shade choices, as dynamic shades can make your switch attract attention, while low-key tones can create a much more classy appearance

Expense vs. Top Quality: Finding the Right Balance

When you're taking care of the options for membrane layer switches, stabilizing cost and high quality can feel frustrating. A lower-cost switch may conserve you money upfront, however if it jeopardizes capability, you could deal with greater replacement costs later on.

Seek makers that use a great mix of price and high criteria. Research their online reputation and consumer evaluations to determine dependability. Often, investing a bit a lot more in quality materials can conserve you from future headaches.

Likewise, consider the long-term efficiency and warranty choices. A a little a lot more costly button with a solid guarantee might confirm to be a smarter investment. Inevitably, it's concerning locating that pleasant area where you fulfill your budget plan while assuring your job's success.

Examining and High Quality Assurance Protocols

While you may find the excellent membrane button style, ensuring its quality through strenuous screening procedures is necessary for lasting success. Start by validating that the maker complies with market requirements, such as IPC/WHMA-A -620, to guarantee a reputable item. membrane switch manufacturer. You'll wish to look for detailed screening techniques, consisting of environmental, mechanical, and electric analyses

Make specific the buttons undertake durability testing, mimicing real-world use to identify any kind Discover More of prospective failures. Pay attention to the supplier's quality guarantee process, which must include routine examinations and audits.

Do not fail to remember to ask for examples and conduct your very own tests to confirm compatibility with your task. Ultimately, consider exactly how often the maker updates their methods; development in testing can result in enhanced top quality. By prioritizing these screening and quality control protocols, you'll raise the chance of a successful and long lasting membrane switch for your application.

Frequently Asked Questions

How much time Does a Membrane Change Typically Last?

A membrane button normally lasts anywhere from 1 to 10 million cycles, relying on use and environmental variables. You'll intend to take right into account your details requirements to assure it fulfills your long life requirements efficiently.

Can Membrane Switches Be Repaired if Damaged?

Yes, you can often repair membrane layer switches if they're damaged, but it typically relies on the extent of the damage. Minor concerns could be reparable, while much more considerable damage generally needs replacement for correct capability.

What Are the Typical Applications for Membrane Layer Buttons?

Membrane layer buttons are commonly made use of in devices, medical gadgets, and automotive controls. You'll find them in customer electronic devices, commercial equipment, and even pc gaming consoles. Their versatility makes them suitable for different individual interfaces and settings.

Exist Certain Certifications for Membrane Switches?

Yes, there specify qualifications for membrane layer buttons. Look for UL, CE, and RoHS qualifications to guarantee safety and conformity. These certifications show the button fulfills sector criteria for top quality and ecological safety and security.

Exactly how Do I Make Sure Correct Installment of a Membrane Switch?

To assure correct installation of a membrane button, tidy the surface extensively, straighten it thoroughly, and use even pressure. Adhere to maker standards for glue curing time to optimize sturdiness and performance.

Conclusion

When picking a membrane button for your project, maintain these essential elements in mind: focus on resilient materials, focus on straightforward layout, and take into consideration customization for your brand. By thoroughly assessing these facets, you'll guarantee your membrane layer button not only fulfills your task requires yet also boosts user experience and mirrors your brand identity properly.

Report this page